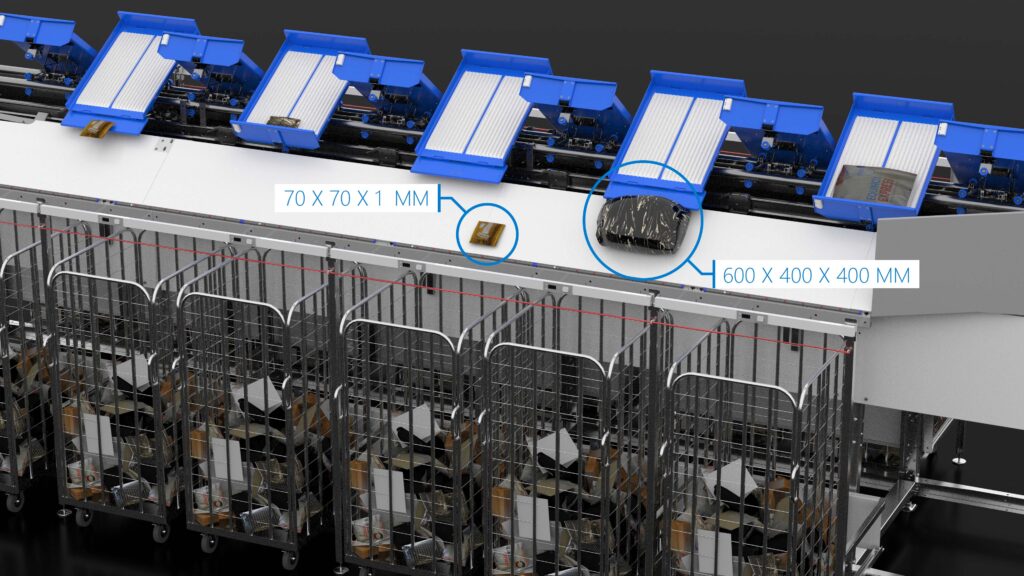

Equinox’s newest LR-sorter is designed to respond to the increased demand for parcel shipping through e-commerce. This compact vertical sorter is fully modular and designed in standard sections. The standard base can be expanded with advanced functions, including infeed options, dimensioning, weighing and scanning (DWS), optical character recognition (OCR) and several output designs.

Primarily, Equinox focused on increasing the maximum throughput, which is now 10,000 items per hour, to enable faster operations and improve overall efficiency. The updated LR-sorter is also a more versatile sorter as it is capable of handling unconventionally proportioned parcels.

Equinox has also reduced the time needed to deliver and install the machine, to reduce downtime when switching between sorters. Installation will now take four days on-site, and can be done in less than three months after signing the contract.

The company streamlined this process by installing the machines in-house to verify that the sorter is fully functional before sending it to the customer.

One of Equinox’s first LR-sorter customers said, “By installing a new machine on the new location instead of moving the existing one, we have eliminated the downtime during the installation. The existing sorter can still be used while the new LR-sorter is being installed. We realized that this option saves us three weeks of downtime. The solution therefore enables us to guarantee a continuous process.”

Equinox has also released a video to demonstrate the newest features, available here.

To read more about the other innovations featured at this year’s Parcel+Post Expo, click here. And to discover this year’s award winners, click here.